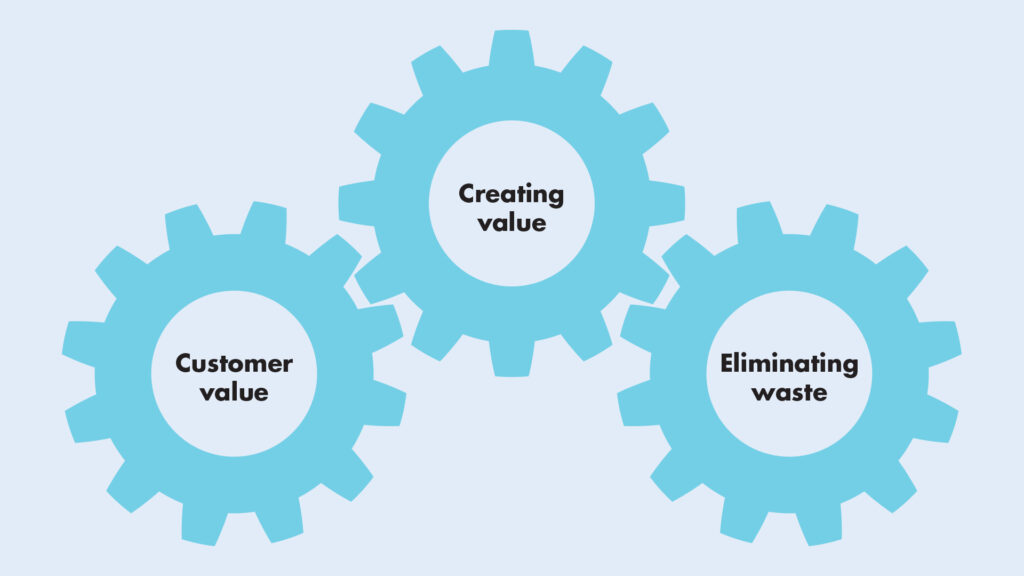

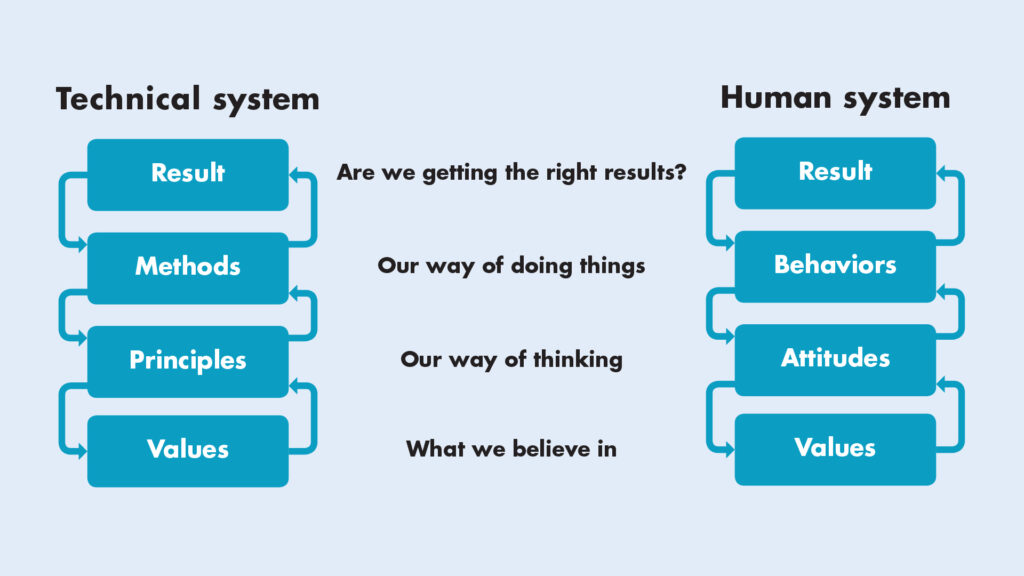

To get the most satisfied customers we have developed an operating system based on LEAN production and our values. The purpose is to simplify and improve how we work and create a corporate culture where everyone is involved and wants to be involved.

The operating system consists of five principles on how to organize our operations to strengthen our competitiveness. The principles are connected – from our understanding of what creates customer value to creating efficient flows that deliver this value.